Mecademic NTO

NTO is an integrator

for Mecademic

Meca500 is the smallest and most precise industrial six-axis robot on the market. It has been developed by Mecademic and represents a new generation of industrial robots.

It weighs just 4.5 kg and has a reach of 260 mm, can pack into less than an A4 page and has a repeat accuracy of 5 micrometres with a payload of 0.5 kg.

NTO represents

Mecademic

Meca500 is the smallest and most precise industrial six-axis robot on the market. It has been developed by Mecademic and represents a new generation of industrial robots.

Do you want to learn more or try out a robot?

Please contact NTO at +45 9715 3344 and ask for Jan or Peter

– world’s smallest, most compact and precise

It is supplied with standard 24VDC, has a built-in webserver/interface via Ethernet, EtherCAT, Ethernet/IP, and ProfiNet. Electronically controlled claws, joystick and the like are an option – ready to ‘plug and play’.

The robot is produced by Mecademic in Canada, and NTO is an integrator for their products.

You can get more information on the robot and the countless possibilities it provides by contacting Jan at jpu@nto.dk, +45 2424 6638 or Peter at pbn@nto.dk, +45 2322 5627. You can also read more on the Mecademic website:

Ultrasonic testing of transducers

I order to test the quality of Piezo ceramic transducers, CTS Ferroperm Denmark has designed and built a test equipment. The test equipment consists of a static ultrasound transmitter placed in a small bowl with still water. The movable part consists of a Meca500 robot with a gripper and ultrasound receiver.

The extreme precision of the Meca500 robot, has made it possible for each Piezo ceramic transducer to be tested very accurate and the exact same way each time.

-

Logistics systems for production and warehouse

NTO has for many years worked on the development of logistics and storage automation for a number of industries.

-

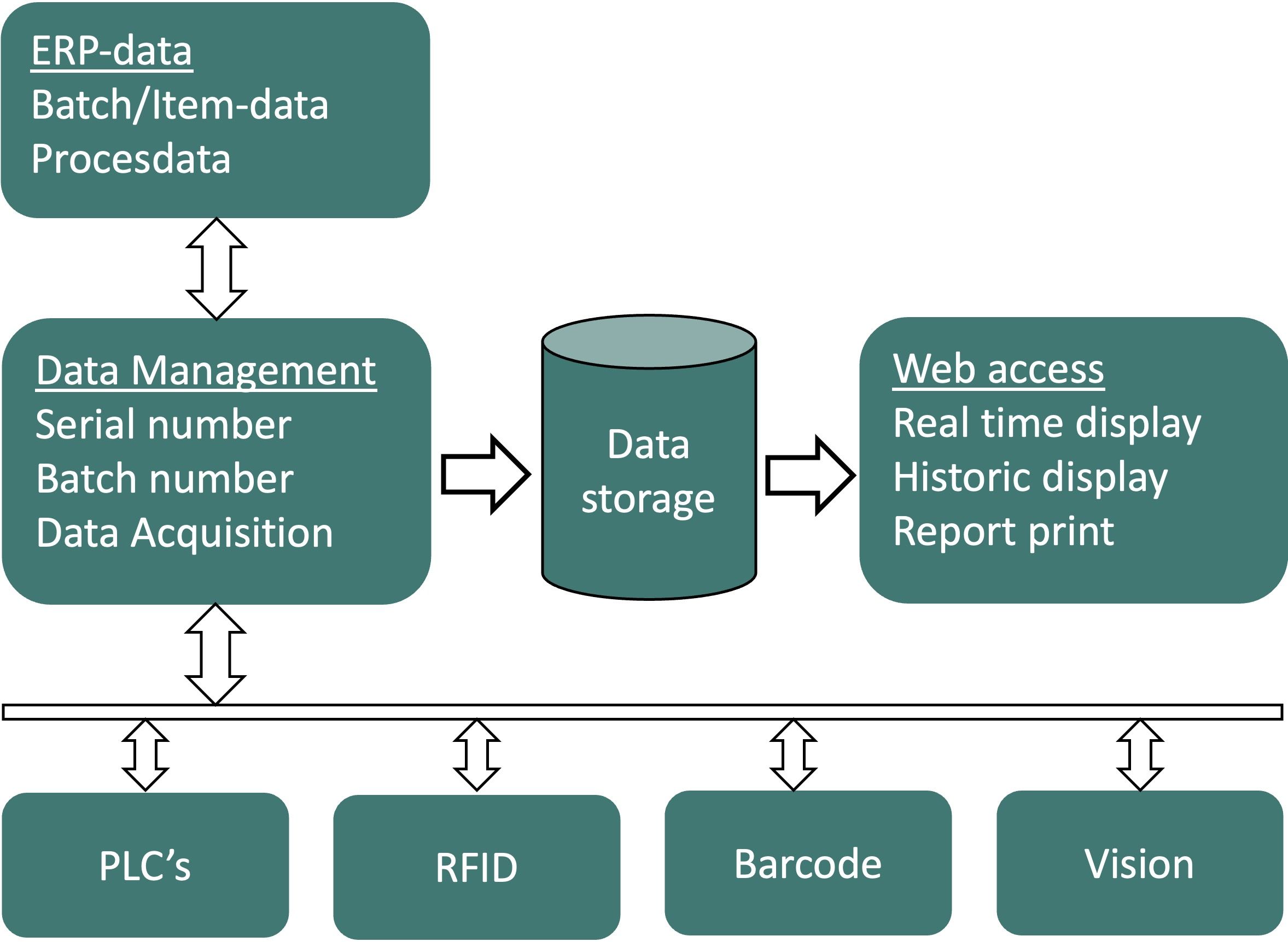

Data management on production lines

Data management is the control of information that needs to flow from the ERP to the production floor and back again. NTO’s systems for data management handle logging of…

-

NTO are experts on IT security on OT network

NTO has through the years delivered many complex internal transport and production solutions. In line with the increased IT threat level, NTO has become specialists in Cyber security.

-

Dolle A/S Frøstrup

Automation at the Dolle A/S production – one of the world’s biggest producers of stairs and European marked leader – has increased production capacity by 50 %.

-

Robot solutions for the ‘green switch’

NTO contributes to the ‘green switch’ by a close collaboration with NewRetex and Ferrum Robotics.

-

Automated robot plastic separation

NTO has a close collaboration with the resource company Nomi4S regarding the separation of plastic from collected household waste.

-

Nomi4s Holstebro

NTO has programmed a new and unique waste management plant at the inter-municipal waste sorting company Nomi4S in Holstebro.

-

Building Management Systems

Intelligent management of buildings is an important part of NTO’s expertise. Within Building Management Systems (BMS), we work on intelligent…

-

NTO is an official ICONICS partner

NTO has worked on the ICONICS SCADA platform for a number of years and became an official ICONICS partner and system integrator in 2019.

-

Billund Airport

The implementation of new options for passengers in Billund Airport is mainly based on NTO’s analysis of the existing luggage handling system.

-

NTO delivers complete machine controls

Since 2003, NTO has delivered complete machine controls for industrial special machines. Among others, we have helped Pressalit A/S with the controls to more than 40 presses.

-

The Cloud system for IOT devices

NTOlink is a Cloud based solution for logging production and incident data. It collects data from controls or IOT equipment that are spread geographically.

-

Complex infrared solution with NTO Vision

NTO has many years of experience with optical vision control systems aimed at foundries.

-

Motion Controls from NTO

Motion Controls provide precise, quick, and controllable positioning, speed or momentum. That is why NTO collaborates with leading manufacturers.

-

NTO Service & Aftersales

NTO has its own Service & Aftersales department, where we handle support in connection with breakdowns, as well as minor adaptations and expansions.

Specialists in Development

NTO A/S · Industrivej 8 · DK-7430 Ikast · Tlf.: +45 9715 3344 · nto@nto.dk